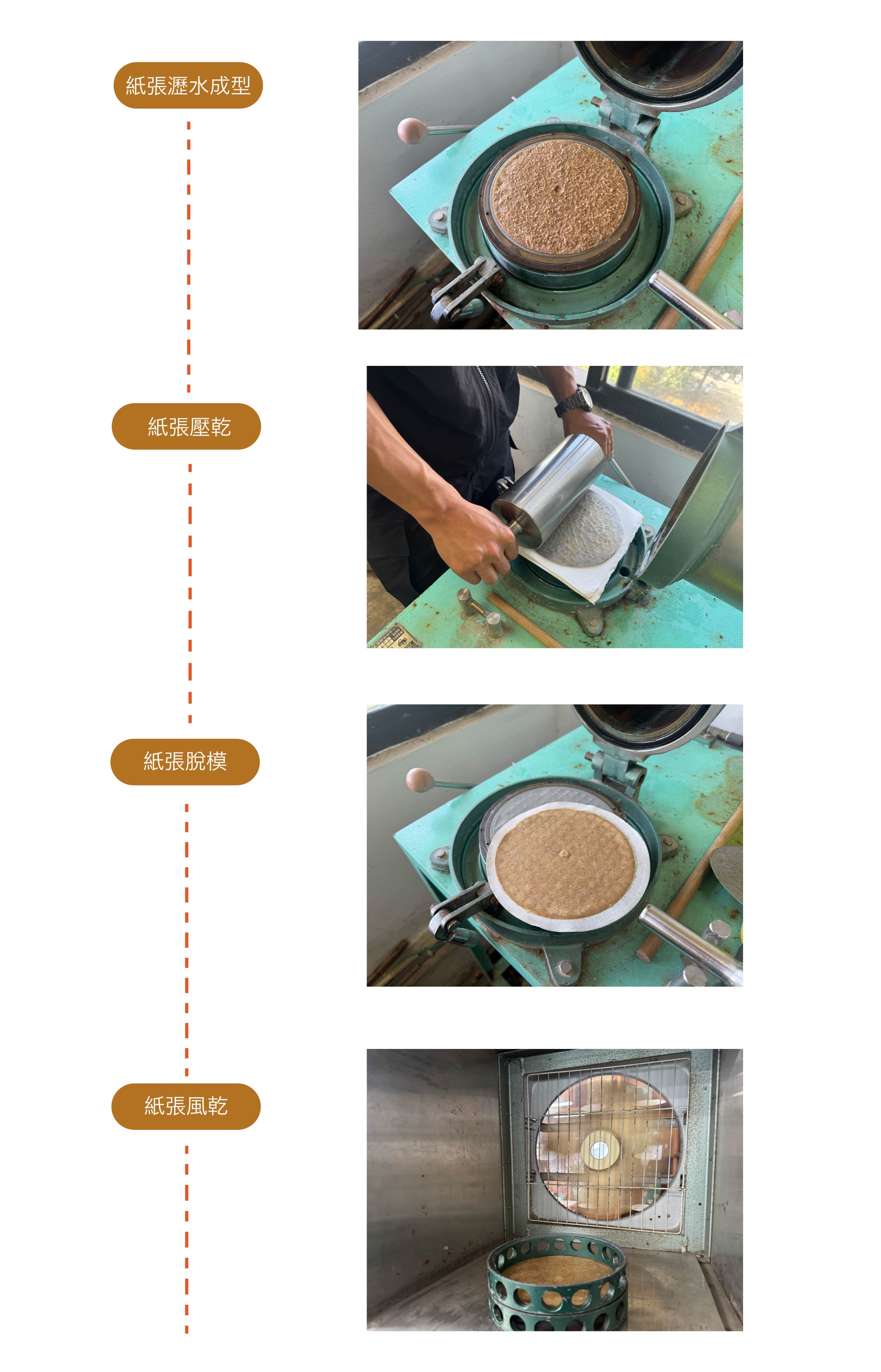

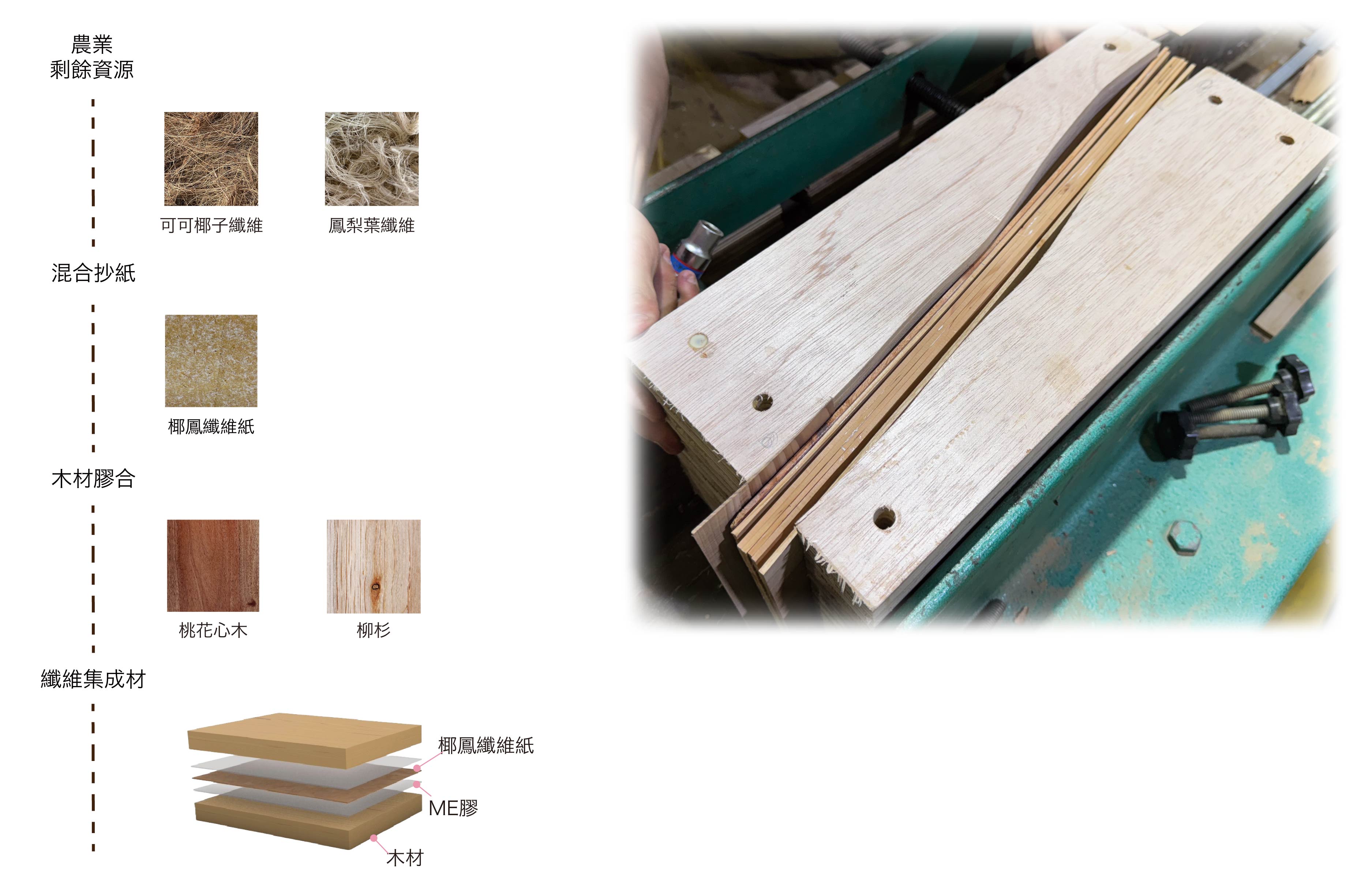

1.椰鳳纖維材料開發與應用

● 以屏東地區的農業剩餘資源為基礎,開發椰鳳纖維材料,加入木製自行車架中提升結構強度。

● 透過實驗得出 7:3比例的椰鳳纖維紙在紙力強度時最佳。

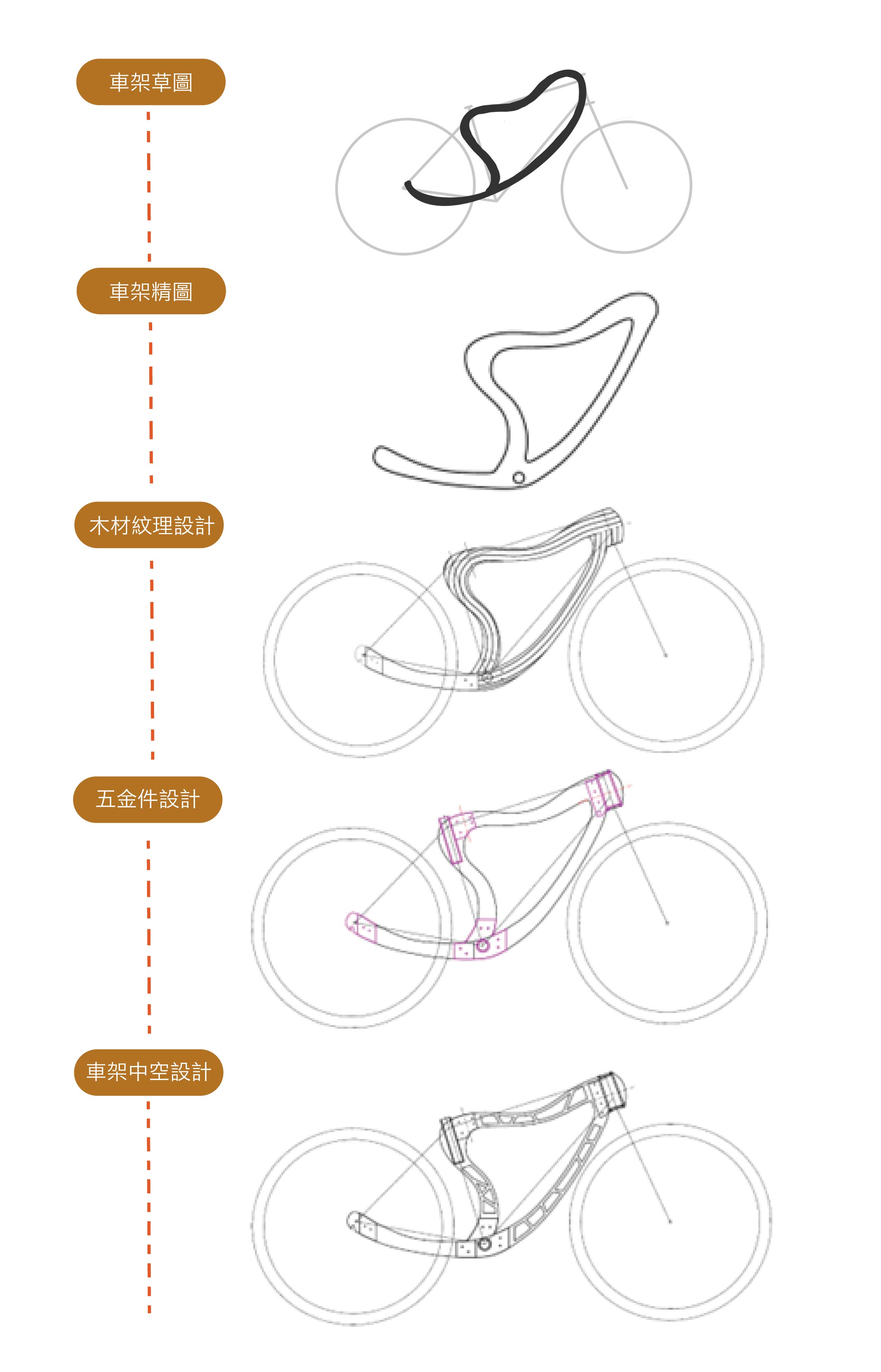

2.自行車架設計

● 參考衛福部統計平均國人男女性身高為 160-170公分,並採用 15-65歲年齡層。

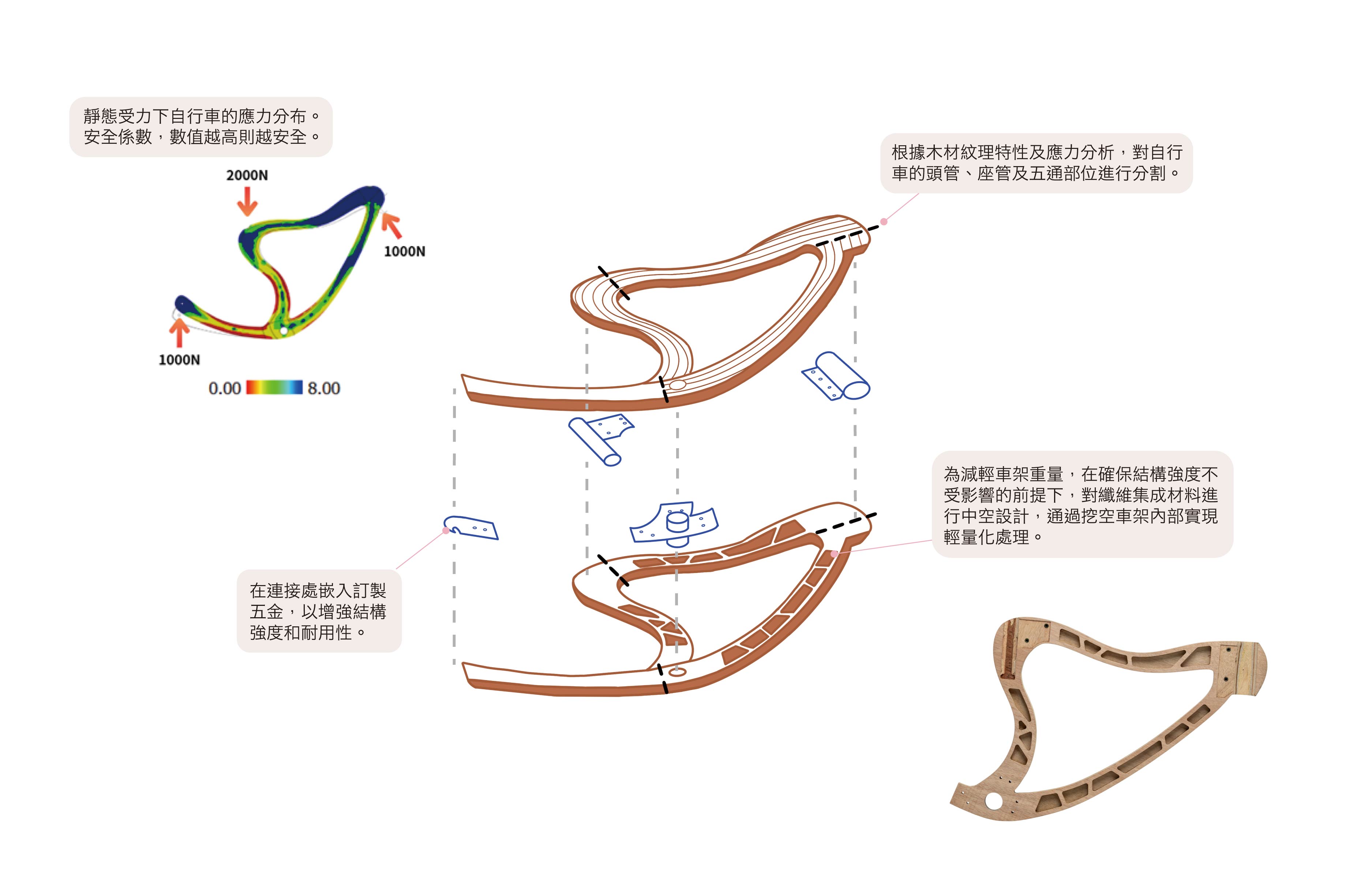

● 根據木材紋理的方向特性與自行車行駛過程中承受的應力分佈,設計出所需的集成方向。

● 自行車的頭管、座管及五通部位進行分割,採不同部件製作使損壞時可更換單一部件。

● 分件接合處嵌入鋁件,以增強結構強度、耐用性及相容性。

● 中空化設計在確保結構強度不受影響的前提下,對集成材料進行通過挖空車架內部實現輕量化處理。

3.效益

● 木製自行車架相較於傳統金屬車架,選用國產木材製作能減少碳排也能固碳,每輛車架可消耗 0.5 kg鳳梨與 1.1 kg椰殼纖維,並固碳 8.43 kg。

● 全台公共單車約 7萬輛,若當中 10 %車輛為纖維複合材自行車,可消耗 3,500 kg鳳梨及 7,700 kg椰殼纖維。

4.椰鳳纖維包裝應用

● 紙塑包材與蜂巢紙具備可回收、可降解特性。

● 成為環保包裝市場的綠色選擇,並取代傳統氣泡紙與保麗龍。透過此循環設計,創造永續解決方案以及經濟價值。

1.Development and Application of Coconut-Pineapple Fiber Materials

● Based on agricultural residual resources in the Pingtung, coconut-pineapple fiber materials are developed and integrated into wooden bicycle frames to enhance structural strength.

● Experimental results indicate that a 7:3 ratio of coconut-pineapple fiber in fiber-based paper yields optimal tensile strength.

2.Bicycle Frame Design

● Considering the average height of Taiwanese men and women (160–170 cm) as reported by the Ministry of Health and Welfare, the design targets individuals aged 15 to 65.

● The integration direction is determined based on the grain orientation of the wood and the stress distribution experienced by the bicycle during operation. The head tube, seat tube, and bottom bracket sections are segmented, allowing for modular manufacturing so that damaged parts can be replaced individually.

● Aluminum components are embedded at the joints to enhance structural strength, durability, and compatibility.

● A hollow design is employed to achieve weight reduction without compromising structural integrity by strategically hollowing out the internal sections of the integrated material.

3.Benefits

● Compared to traditional metal frames, wooden bicycle frames made from domestically sourced timber contribute to carbon reduction and sequestration. Each frame utilizes approximately 0.5 tons of pineapple leaves and 1.1 tons of coconut shells while sequestering 8.43 kg of carbon.

● With around 70,000 public bicycles in Taiwan, if 10% were made from natural fiber-reinforced composite wood, an estimated 3,500 kg of pineapple leaves and 7,700 kg of coconut.

4.Application of Coconut-Pineapple Fiber in Packaging

● Paper-plastic composite materials and honeycomb paper possess recyclable and biodegradable properties, making them eco-friendly alternatives for packaging.

● These materials can replace traditional bubble wrap and polystyrene foam. This circular design approach fosters sustainable solutions while generating economic value.