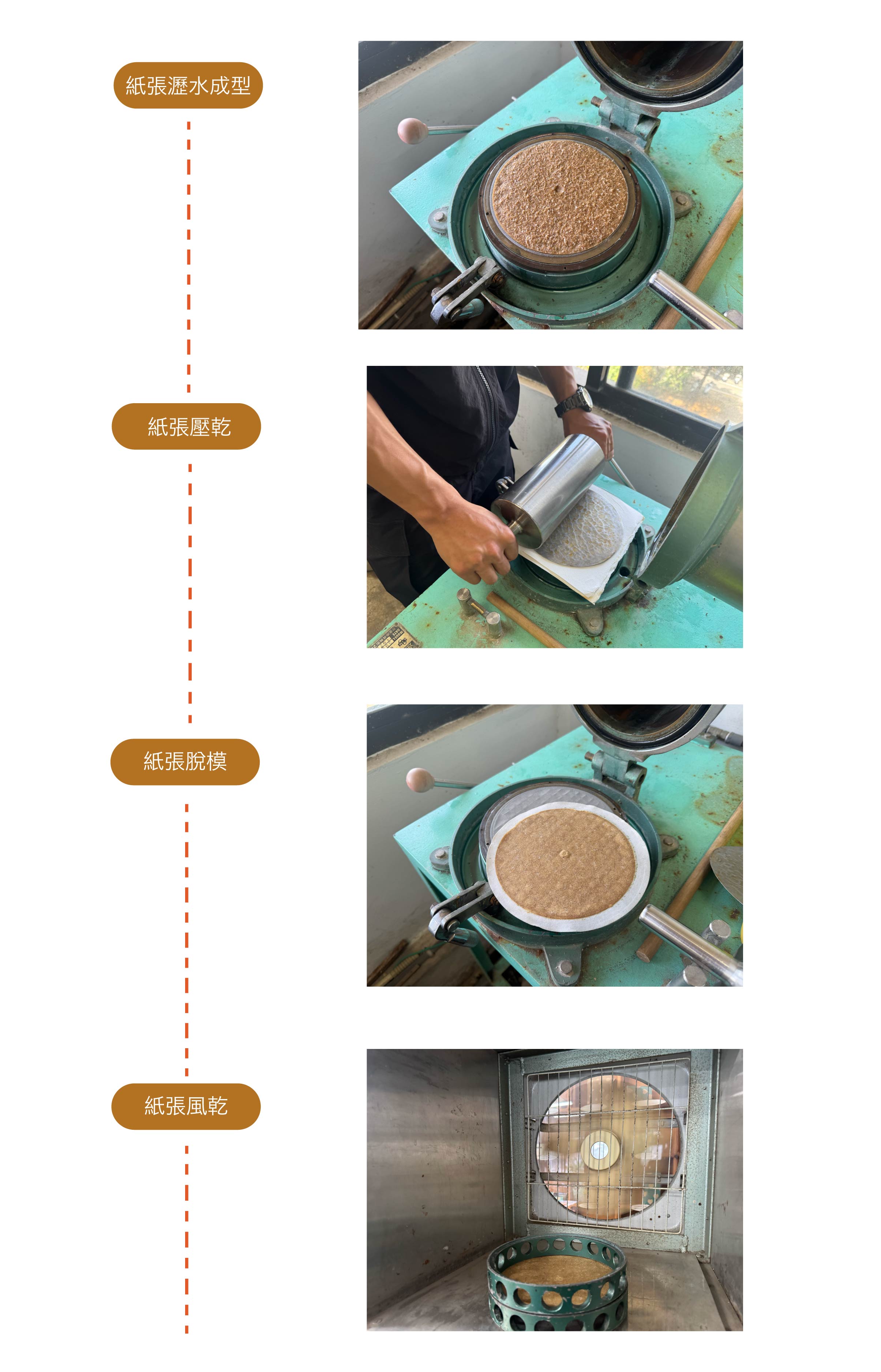

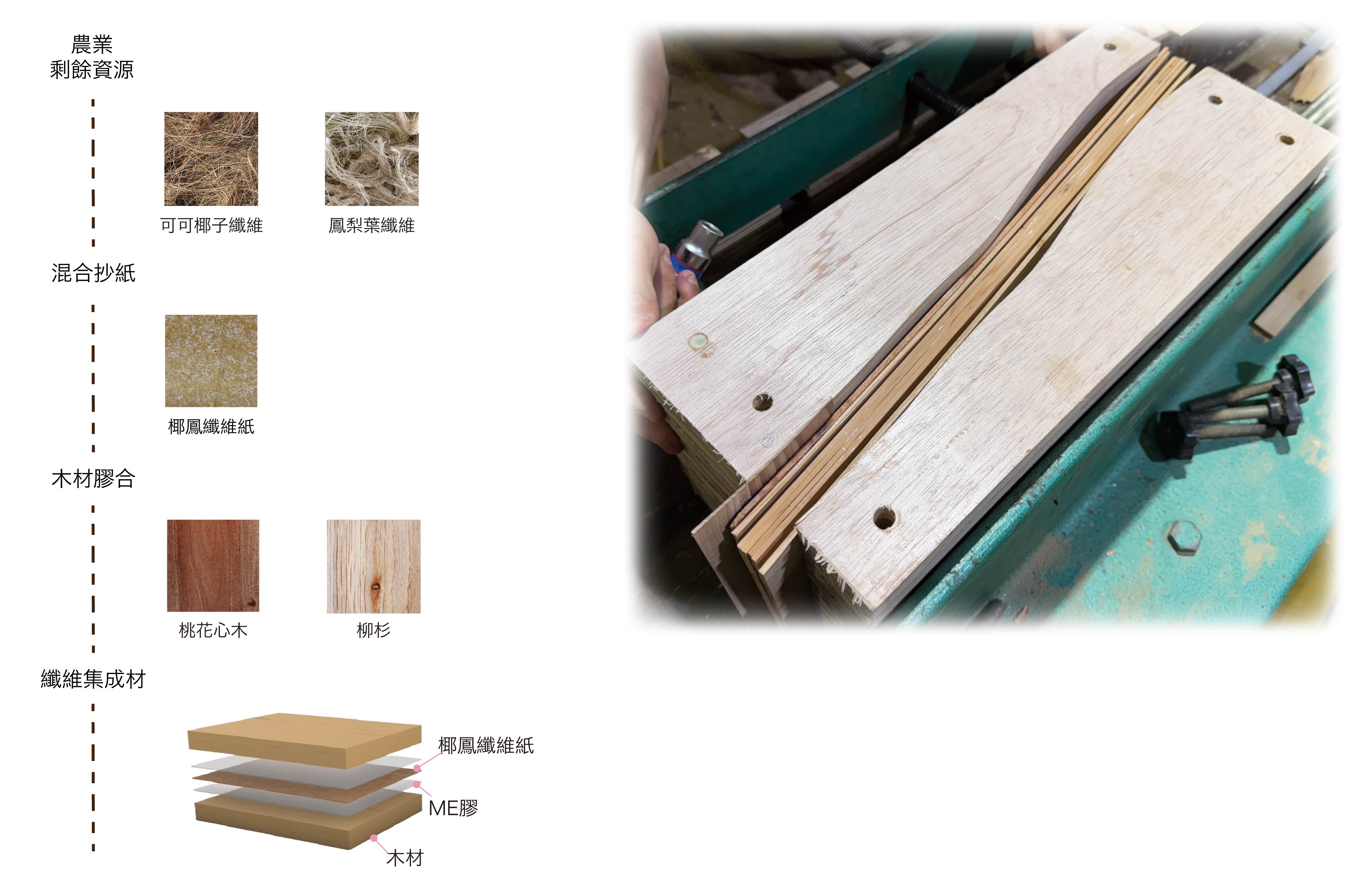

1.椰鳳纖維材料開發與應用

● 利用屏東地區的農業剩餘資源,開發椰鳳纖維材料。

● 透過實驗得出 7:3比例的椰鳳纖維紙在紙力強度時最佳,纖維紙含浸膠與木材製作纖維集成材,在膠合剪斷強度及抗彎強度上皆提升材料性能,並應用於木製自行車架與環保包裝。

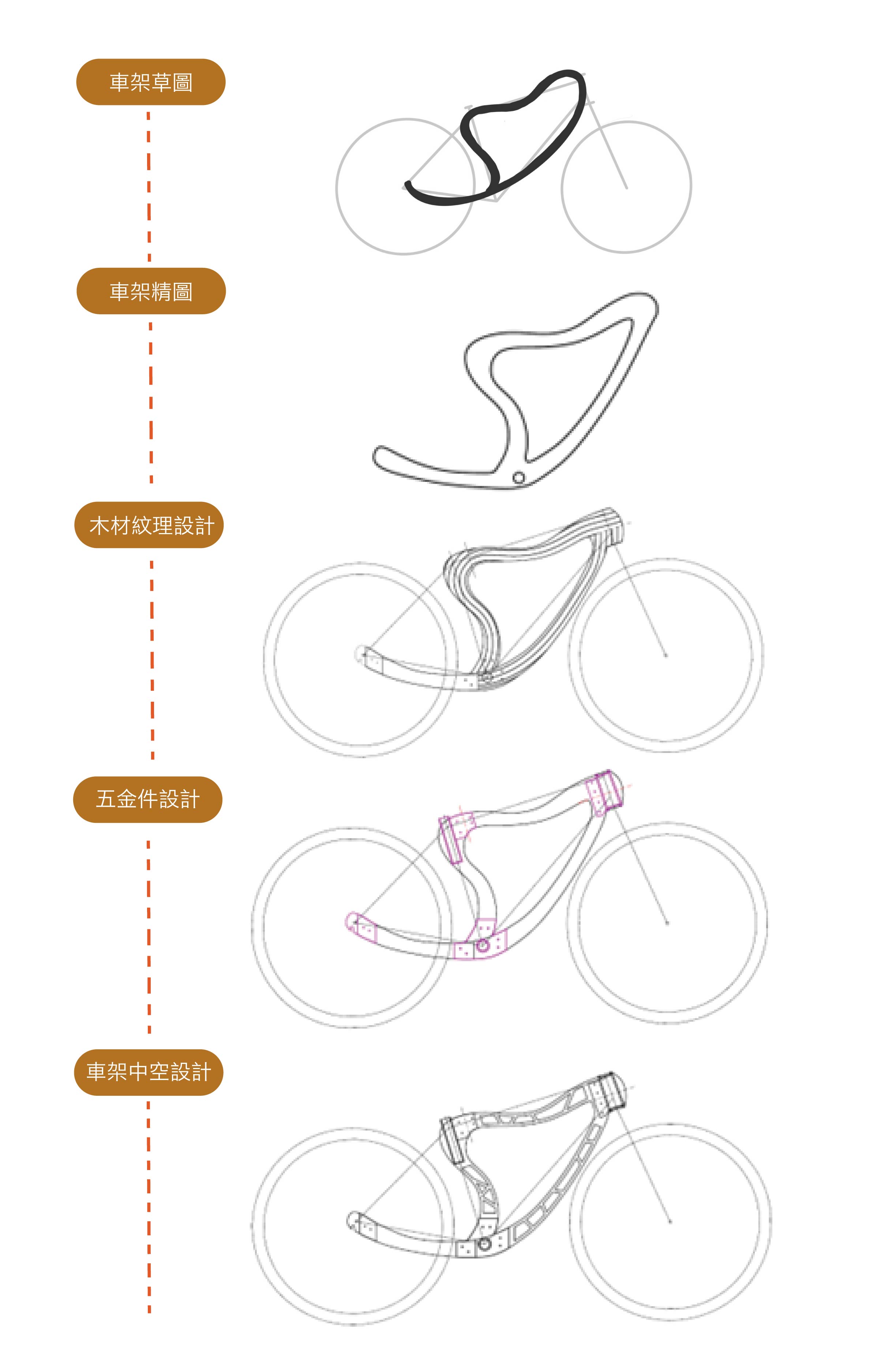

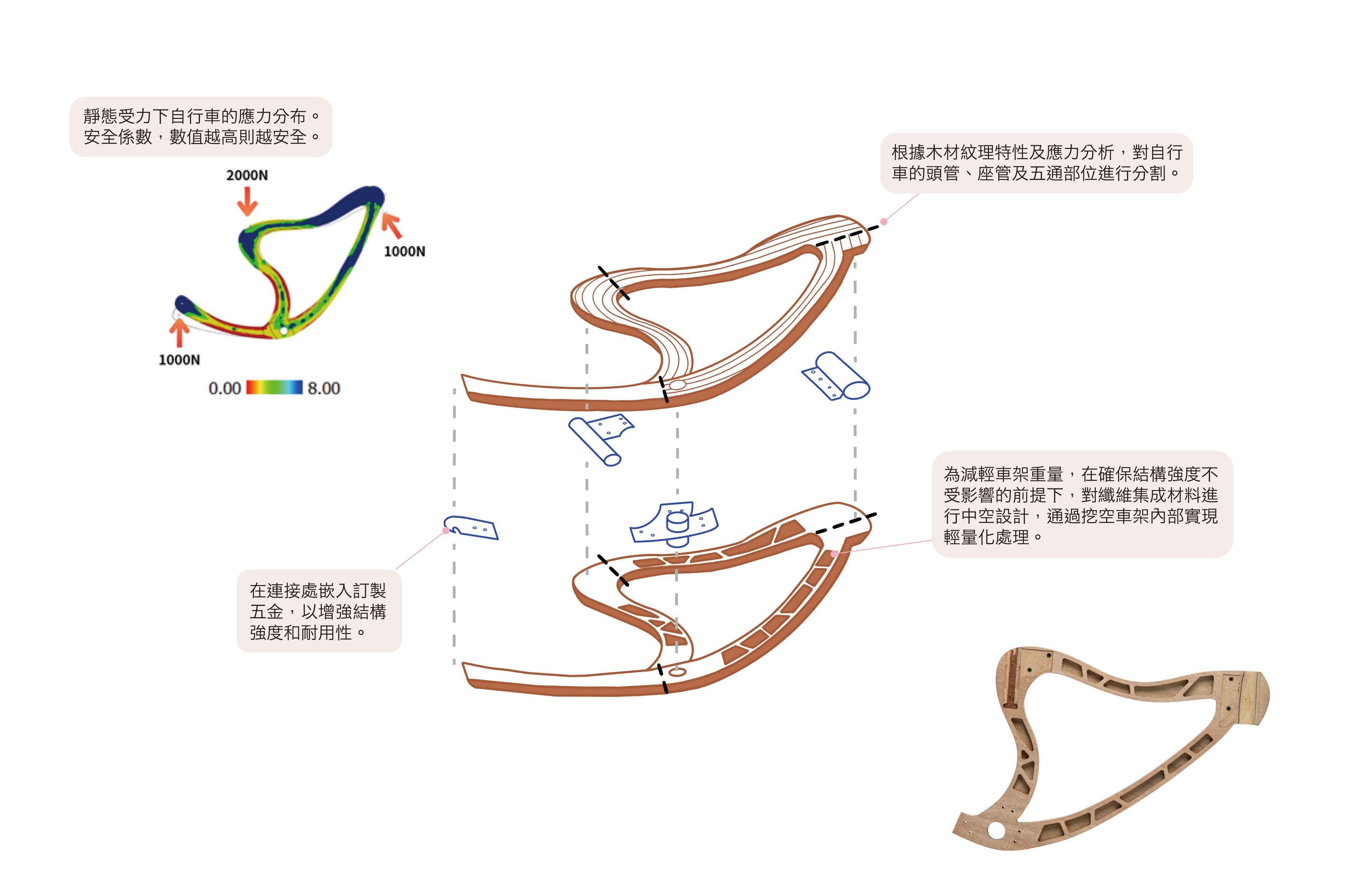

2.自行車車架設計

● 車架設計以蝴蝶翅膀為靈感,賦予自行車輕盈、優雅的曲線造型及現代感,體現自然與文化的融合。

● 搭配模具冷壓實木薄片製作曲型車架,更有機會被量產化製作。

● 車架中空化設計,將內部挖空使車架更為輕量化。

● 車架分為不同部件製作,在損壞時可更換單一部件維修。

● 分件接合處搭配鋁件,在確保強度的同時也能使其與一般自行車配件有更佳的適配性,使其與一般自行車無異。

3.效益

● 每製造一輛木製自行車架,可消耗 0.5 kg鳳梨與 1.1 kg椰殼纖維,且車架固碳達 8.43 kg。

● 全台公共單車約 7萬輛,若當中 10 %車輛為纖維複合材自行車,可消耗 3,500 kg鳳梨及 7,700 kg椰殼纖維。

4.椰鳳纖維包裝應用

● 蜂巢紙及紙塑包材具備可回收、可降解特性。

● 取代傳統氣泡紙與保麗龍包裝,成為環保包裝市場的綠色選擇。透過此循環設計,創造永續解決方案以及經濟價值。

1.Development and Application of Coconut-Pineapple Fiber Materials

● Agricultural residual resources from Pingtung are utilized for the development of coconut-pineapple fiber materials.

● Experimental results indicate that a 7:3 ratio of coconut-pineapple fiber in fiber-based paper yields optimal tensile strength.

● Fiber paper is impregnated with adhesive and combined with wood to produce fiber-reinforced composite materials, its shear bonding strength and flexural strength

are significantly enhanced. These materials are further applied in the manufacturing of wooden bicycle frames and eco-friendly packaging.

2.Bicycle Frame Design

● Inspired by the structure of butterfly wings, the frame design incorporates lightweight, elegant curves that embody a fusion of nature and culture with a contemporary aesthetic.

● The frame is fabricated using cold-pressed solid wood veneers in a mold, facilitating the feasibility of mass production. A hollow-frame design is adopted by strategically removing internal material to achieve weight reduction.

● The modular design divides the frame into separate components, allowing for the replacement of individual parts in case of damage.

● Aluminum inserts are incorporated at the joint sections to ensure structural integrity while enhancing compatibility with standard bicycle components, making the wooden bicycle functionally equivalent to conventional bicycles.

3.Benefits

● The production of each wooden bicycle frame repurposes approximately 0.5kg of pineapple leaves and 1.1 kg of coconut shells, contributing to a carbon sequestration capacity of 8.43 kg per frame.

● With around 70,000 public bicycles in Taiwan, if 10% were made from natural fiber-reinforced composite wood, an estimated 3,500 kg of pineapple leaves and 7,700 kg of coconut.

4.Application of Coconut-Pineapple Fiber in Packaging

● Honeycomb paper and paper-plastic composite materials possess recyclable and biodegradable properties.

● These materials serve as sustainable alternatives to traditional bubble wrap and polystyrene packaging, making them a greener choice for the eco-friendly packaging industry. Through this circular design approach, sustainable solutions and economic value are created.