DIY機油瓶

Quick-O-Bottle

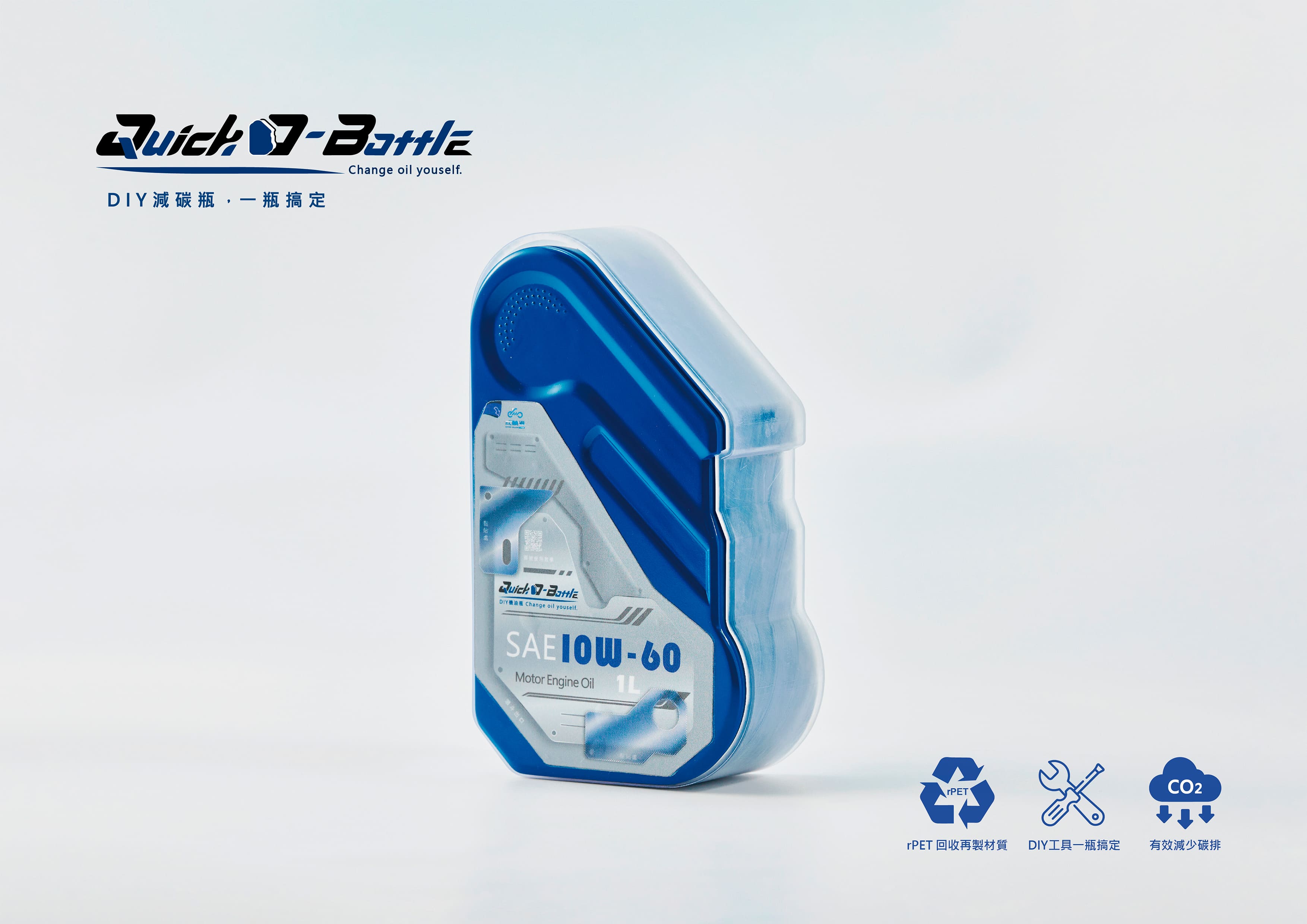

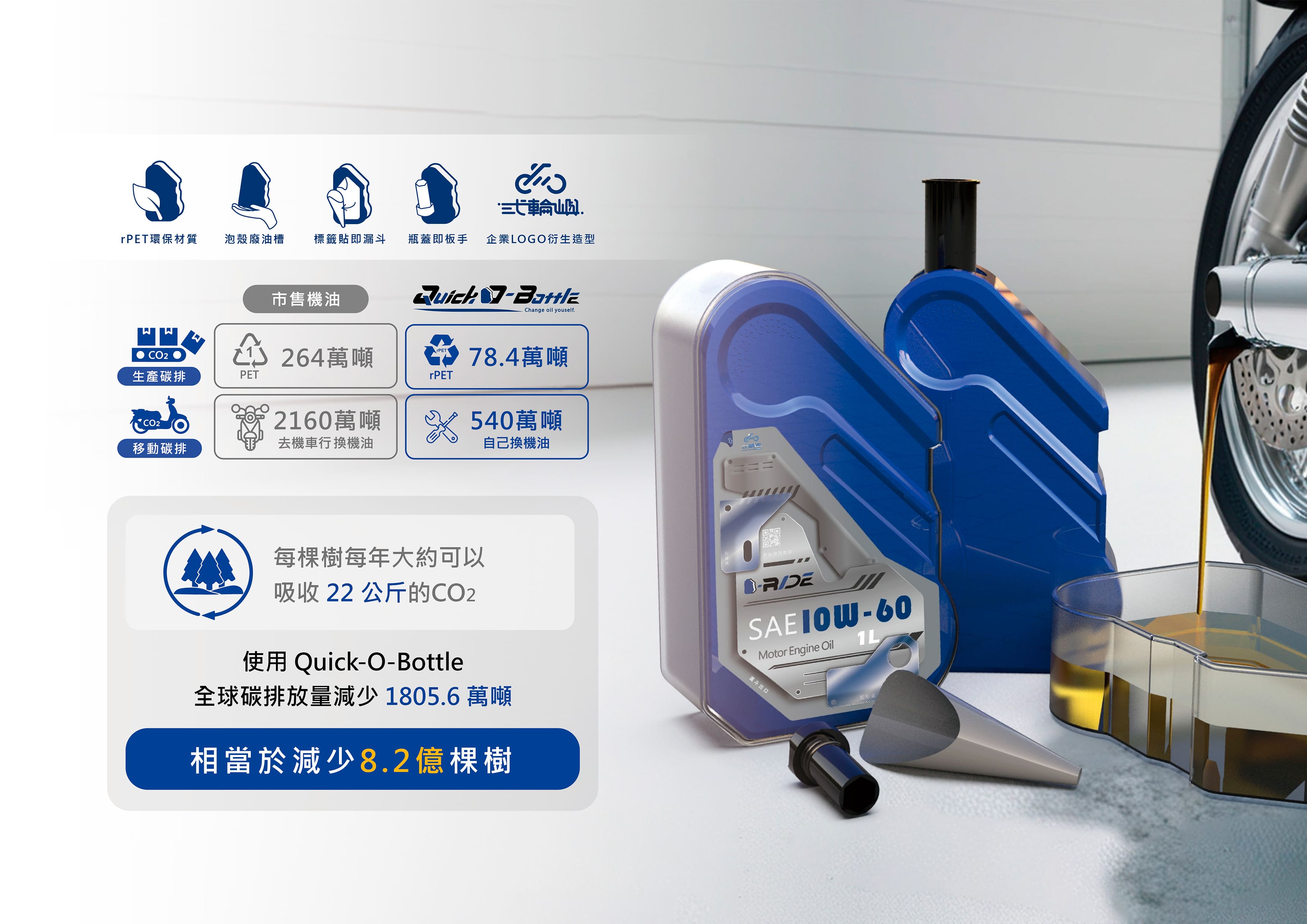

Quick O-Bottle 是一款讓使用者可自行更換機油的創新包裝工具組,內含三種工具:標籤貼即撕漏斗、瓶蓋六角扳手及廢油收納盒,簡單六步驟,即可快速便利地完成換油,無論長途旅行或戶外環境,都能確保機車維護的即時性,降低損壞風險。

全瓶身採用 100% rPET 再生環保材質,不僅有效保存機油品質,也減少對原生 PET 材質的依賴,降低能源消耗與碳排放。透過循環設計概念,瓶身與工具一體化,使所有部件皆可回收,省去回收時拆除標籤的步驟,同時減少額外工具的生產與使用,進一步降低環境負擔。

在循環經濟模式下,使用後的 Quick O-Bottle 可回收再製成新的機油瓶,形成封閉式循環系統,每年可減少 40 億個廢棄機油瓶對環境的影響,實現資源最大化利用,推動機車維護的永續發展。

Quick-O-Bottle

Quick O-Bottle is an innovative packaging toolset that enables users to perform oil changes independently. It includes three integrated tools: a tear-off label that functions as a funnel, a hexagonal wrench bottle cap, and a waste oil collection box. With a simple six-step process, users can quickly and conveniently complete an oil change, ensuring timely motorcycle maintenance and reducing the risk of mechanical failure, whether on long journeys or in remote areas.

The entire bottle is made from 100% recycled PET (rPET) material, effectively preserving oil quality while reducing reliance on virgin PET materials, thereby lowering energy consumption and carbon emissions. Through a circular design concept, the bottle integrates necessary oil change tools, making all components recyclable. This design eliminates the need to remove labels during recycling and reduces the production and use of additional tools, further decreasing environmental impact.

Within a circular economy framework, used Quick O-Bottle units can be returned to manufacturers for recycling, where the rPET material is reprocessed into new oil bottles, re-entering the market. This closed-loop system minimizes the production of new bottles and associated energy waste. Annually, this approach can significantly reduce the environmental burden of disposing of billions of oil bottles, maximizing resource utilization and promoting sustainable development in motorcycle maintenance.

亞洲大學 創意商品設計學系

(四年級)

石子平

亞洲大學 創意商品設計學系

(四年級) 指導老師 劉芃均